Blog description in detail:

Packaging boxes are containers made of various materials, such as cardboard, paperboard, corrugated fiberboard, or plastic, used to protect, store, and transport goods during shipping or handling. They come in various shapes and sizes, from small boxes for retail packaging to large boxes for bulk shipments. The importance of packaging boxes in the packaging industry cannot be overstated. They provide a reliable and cost-effective means of protecting goods from damage during transit or storage, minimizing the risk of loss or spoilage. Box packaging also serves as a branding tool, as companies can print their logos, slogans, and other marketing messages on them, which helps to promote their products and enhance their visibility in the marketplace.

Future and Market share of Packaging Boxes

The packaging industry in the United States is a major contributor to the country's economy, generating billions of dollars in revenue and providing employment opportunities to thousands of people. According to a report by IBISWorld, the U.S. packaging industry is expected to reach $193.3 billion in revenue by 2024, driven by population growth, increased consumer spending, and rising demand for e-commerce packaging. The U.S. packaging industry is diverse, with numerous manufacturers and suppliers offering various products and services. Some of the key players in the sector include International Paper, WestRock, Sealed Air, and Amcor. These companies produce a wide range of packaging products, including boxes, bags, pouches, and other types of containers used for various applications, such as food and beverage packaging, pharmaceutical packaging, and industrial packaging.

Design Considerations for Custom Packaging Boxes

When designing custom packaging boxes with logos, several considerations must be considered to ensure the packaging effectively protects the product and enhances its presentation. Some of the key design considerations for custom packaging boxes are:

Material

The choice of material is crucial when designing custom packaging boxes. The material should be strong enough to protect the product from damage during transit and storage yet lightweight enough to minimize shipping costs. For example, corrugated fiberboard is commonly used for custom packaging boxes, providing strength and lightness. Other materials, such as plastic or paperboard, may be used depending on the product's needs and the desired level of protection.

Size and Shape

The size and shape of the packaging box should be tailored to the product's dimensions to ensure a snug fit, reducing the risk of damage during transit. The body of the packaging box should also be designed to fit the product's shape and form, optimizing its visual appeal. For example, custom packaging boxes for cosmetics may be designed to provide the product's unique shape and form, enhancing its visual appeal.

Branding and Graphics

Custom packaging boxes should be designed with branding and graphics that reflect the product and the company's brand identity. This can include logos, product images, and other marketing messages. The design should be visually appealing and communicate the product's unique features and benefits to the customer.

Functionality

The packaging box should be easy to use, with features such as handles, tear strips, or easy-to-open lids. The packaging box's design should also consider the end user's needs, such as providing a way to store or display the product. For example, custom packaging boxes for food products may include a built-in tray or divider to separate different food items and prevent them from mixing during transit.

Sustainability

Sustainable packaging is becoming increasingly important, and the design of custom packaging boxes should consider this. The packaging should be made from recyclable or biodegradable materials, and the design should minimize waste and environmental impact. For example, custom packaging boxes may be designed to use minimal materials or feature recyclable materials to reduce waste.

Cost

The design of the custom packaging box should balance the need for functionality and visual appeal with cost considerations. The packaging box's design should be optimized for manufacturing efficiency, minimizing the cost of materials and production. For example, custom packaging boxes may be designed with a simple shape or require minimal assembly to reduce manufacturing costs.

The design of custom packaging boxes should be tailored to the product's needs and reflect the company's brand identity while considering sustainability and cost considerations. By considering these factors, custom packaging boxes can be designed to protect the product, enhance its presentation, and minimize environmental impact and cost.

Advantages and Disadvantages of Custom Packaging for small business

Custom packaging offers several advantages and disadvantages for small businesses. Here are some of the key pros and cons:

Advantages of Custom Packaging

Branding

Retail box packaging allows small businesses to create packaging that reflects their brand identity, with logos, colors and designs that distinguish their products from competitors.

Customer Experience

Custom packaging can enhance the customer experience by providing easy-to-use, visually appealing packaging and reflecting the product's value.

Protection

Custom packaging can be designed to provide superior product protection, reducing the risk of damage during transit and storage.

Marketing

Custom packaging can be used as a marketing tool, with marketing messages and product information incorporated into the design.

Differentiation

Custom packaging allows small businesses to differentiate their products from competitors, creating a unique selling proposition that can help drive sales.

Product Differentiation

Custom packaging allows small businesses to differentiate their products and stand out in a crowded market. Unique packaging designs can attract customers and help build brand recognition.

Improved Product Perception

High-quality custom packaging can improve customers' perception of the product's value, increasing sales and customer loyalty.

Better Protection

Custom packaging can be designed to provide better protection for fragile or sensitive products. This can reduce returns and damage claims, saving small businesses money in the long run.

Sustainability

While custom packaging may have a higher environmental impact than standard packaging, businesses can choose eco-friendly materials and designs to reduce their environmental impact. This can improve a business's reputation with customers who value sustainability.

Flexibility

Custom packaging offers small businesses more design, size, and shape flexibility. This can be particularly beneficial for companies with unique or irregularly shaped products.

Disadvantages of custom packaging

More Expensive

Custom packaging can be more expensive than standard packaging, particularly for small businesses with limited budgets.

Requires more time

Custom packaging requires time to design and manufacture, which can delay product launch or impact production schedules.

Minimum Order Restrictions

Some manufacturers require minimum order quantities for custom packaging, which may need to be lowered for small businesses.

Inventory Management

Custom packaging may require additional inventory management, as businesses need to keep track of multiple SKUs for different packaging designs.

Sustainability

Custom packaging may have a higher environmental impact than standard packaging, particularly if it requires additional materials or needs to be recyclable.

Design Challenges

Designing custom packaging can be challenging, particularly for businesses that need to gain experience in packaging design. This can result in less effective packaging that protects the product or is appealing to customers.

Manufacturing Challenges

Custom packaging may require specialized equipment or processes to manufacture, which can be more expensive or time-consuming than standard packaging.

Shipping Challenges

Custom packaging may require additional packaging materials or precautions during shipping to ensure products arrive undamaged. This can increase shipping costs and potentially delay delivery times.

Limited Reusability

Custom packaging may not be reusable, which can be a disadvantage for businesses that promote sustainability or want to encourage customers to reuse packaging.

Limited Flexibility

Once a small business has invested in custom packaging, it can be difficult to change designs or materials without incurring additional costs. This can limit a business's flexibility to adapt to changing market conditions or customer preferences.

Packaging boxes for small businesses should carefully weigh the advantages and disadvantages of custom packaging before deciding. While custom packaging offers several benefits, some companies may have better choices, depending on their budget, production needs, and environmental priorities.

Trends in Cardboard Packaging Boxes

Use of Sustainable Materials: There is a growing trend in using sustainable materials in cardboard packaging boxes. Many businesses opt for eco-friendly materials such as recycled cardboard, biodegradable plastics, and plant-based materials. This is driven by increasing consumer demand for environmentally friendly products and a desire to reduce the environmental impact of packaging.

Smart Packaging Technology

Another trend in cardboard packaging boxes is the use of smart packaging technology. This includes features such as RFID tags, QR codes, and other sensors that can provide information about the product or help with inventory management. Smart packaging can also be used to monitor the condition of products during shipping and storage.

Minimalistic Design

Minimalistic design is also becoming more popular in cardboard packaging boxes. This involves using simple, clean, easy-to-read, and visually appealing methods. Minimalistic design can help products stand out on store shelves and convey a sense of quality and sophistication.

Customization

Customization is another trend in cardboard packaging boxes. Many businesses opt for custom packaging designs that reflect their brand identity and product characteristics. This includes using unique colors, graphics, and other design elements to make their products stand out from competitors.

Functional Design

Functional design is also becoming more important in cardboard packaging boxes. This includes features such as easy-to-open packaging, ergonomic shapes, and other design elements that improve the user experience. Functional design can help businesses create packaging that is more convenient and appealing to customers.

Interactive Packaging

Interactive packaging is a trend that involves creating packaging that engages consumers uniquely and memorably. This can include features such as augmented reality, puzzles, and other interactive elements that make a more immersive experience for the customer.

Personalization

Personalization is becoming increasingly important in cardboard packaging boxes. This involves creating packaging tailored to individual consumers, including their names or other personalized elements. Personalization can create a stronger connection between the customer and the brand and make the product feel more special and unique.

Lightweight Packaging

As sustainability becomes more important, lightweight packaging is becoming a popular trend. Lightweight packaging reduces the amount of material used, which can reduce costs and improve the environmental impact of packaging. Additionally, lightweight packaging can be easier to handle and transport, improving efficiency in the supply chain.

Creative Shapes

Creative shapes are another trend in cardboard packaging boxes. This involves creating packaging that has a unique and innovative shape, such as a triangular or hexagonal box. Creative shapes can help products stand out on store shelves and create a more memorable and distinctive brand image.

Multi-Functional Packaging

Multi-functional packaging is becoming more popular as businesses seek to create packaging that serves multiple purposes. For example, a cardboard box could be designed to double as a display stand or storage container. Multi-functional packaging can create additional value for customers and reduce waste, improving the environmental impact of packaging. These trends in cardboard packaging boxes reflect consumers' and businesses' changing needs and preferences and the evolving role that packaging plays in the overall brand experience. As companies continue to innovate and experiment with new packaging designs and materials, we can expect to see more exciting trends emerge in the years to come.

Regulations and Standards for Branded Packaging in The United States

Federal Trade Commission (FTC) Regulations

The FTC is a government agency that regulates advertising and marketing practices in the United States. Regarding packaging, the FTC regulates claims made on packaging, such as claims about the health benefits of a product or its environmental impact. The FTC requires that any claims made on the packaging be truthful, substantiated, and not misleading.

For example, suppose a company claims that its product is "all-natural" on the packaging. In that case, it must substantiate that claim with evidence that the product contains only natural ingredients. If a company claims its product is biodegradable, it must have evidence to support it and ensure that the packaging is compostable in a reasonable time frame.

Food and Drug Administration (FDA) Regulations

The FDA regulates the use of packaging for food and pharmaceutical products. This includes regulations on labeling and packaging materials to ensure that they are safe for use and do not contaminate the product.

For example, the FDA requires that food packaging be made from materials that are safe for use with food and do not transfer harmful chemicals or substances to the food. The FDA also regulates the labeling of food packaging, requiring that it accurately reflects the contents and nutritional information of the product.

Environmental Protection Agency (EPA) Regulations

The EPA regulates the use of packaging materials and their environmental impact. This includes regulations on the disposal of packaging materials and using environmentally friendly materials.

For example, the EPA encourages companies to use packaging materials that are recyclable or made from recycled materials. The EPA also regulates the disposal of packaging materials, requiring companies to ensure that they are properly disposed of or recycled to reduce waste and environmental impact.

ASTM International Standards

ASTM International is a leading standards organization for the packaging industry. They develop and maintain standards for packaging materials, testing methods, and performance requirements.

For example, ASTM has developed standards for the strength and durability of packaging materials and for the safety and performance of child-resistant packaging.

International Organization for Standardization (ISO) Standards

ISO is an international standards organization that sets standards for various industries, including the packaging industry. They develop and maintain standards for packaging materials, design, and testing.

For example, ISO has developed standards for labeling packaging materials, including requirements for the placement and readability of labels. They have also set standards for testing packaging materials to meet safety and performance requirements.

Sustainable Packaging Coalition (SPC) Standards

The SPC is a non-profit organization that promotes sustainable packaging practices. They develop and maintain standards for environmentally friendly packaging materials and design.

For example, the SPC has developed standards for using sustainable materials in packaging, such as using recycled or renewable materials. They have also set standards for packaging design to minimize waste and environmental impact.

By adhering to these regulations and standards, companies can ensure that their branded small packaging boxes are safe, environmentally friendly, and accurately represents their products. They can also avoid fines and legal issues related to false or misleading advertising and promote sustainable practices that benefit their business and the environment.

Types of Packaging Boxes Wholesale

Various kinds of packaging boxes can be purchased wholesale, including:

Corrugated boxes

These are the most common packaging boxes used for shipping and storage. They are made from corrugated cardboard, which provides cushioning and protection for the contents inside.

Folding cartons

These are lightweight, flat boxes commonly used for packaging retail products, such as cosmetics and food items. They can be made from various materials, including paperboard and plastic.

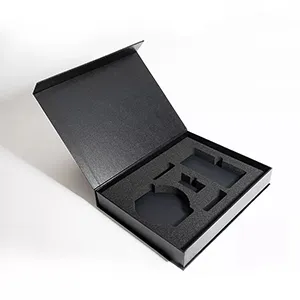

Rigid boxes

These are sturdy, durable cheap packaging boxes often used for high-end retail products, such as jewelry and electronics. They are made from thick cardboard or plastic and can be customized with various finishing options, such as embossing and foil stamping.

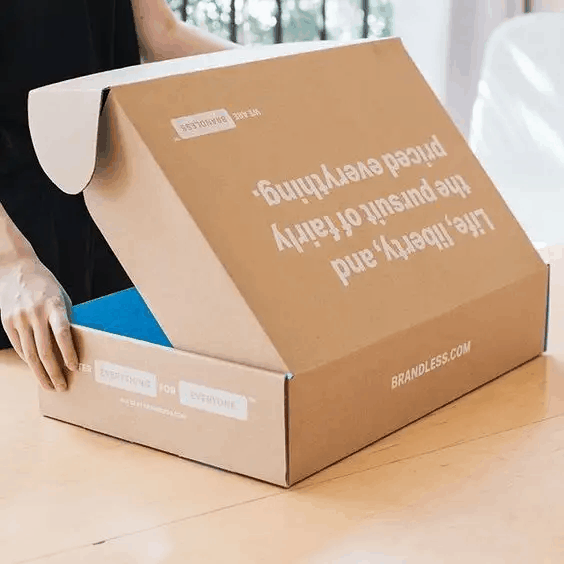

Mailer boxes

These are self-sealing boxes designed to be shipped without additional packaging materials, such as packing tape or bubble wrap. E-commerce businesses commonly use them and can be customized with branding and printing options.

Specialty boxes

These are unique packaging boxes that are designed for specific products or industries. Examples include wine bottle boxes, pizza boxes, and bakery boxes.

Display boxes

These are boxes that are designed to be used for in-store displays or promotional events. They can be made from various materials, including cardboard, plastic, and metal.

Subscription boxes

These boxes are designed for subscription-based services, such as monthly snacks or beauty boxes. They can be customized with branding and printing options to create a unique and memorable unboxing experience for subscribers. Many types of packaging boxes are available for wholesale purchase, each with special features and benefits. Businesses can choose the packaging box that best fits their product and branding needs.

Your email address will not be published. Required fields are marked