Blog description in detail:

Choosing the custom box sizes is essential to ensure products are properly protected and secured during transport. Here are some factors to consider when determining the appropriate box size for your packaging needs:

Size and Weight of the Products Being Packaged

The size and weight of the packaged products are crucial factors to consider when selecting a box size. The box must be large enough to accommodate the products without causing any damage but not so large that the products can shift around during transport. It's essential to measure the dimensions of the products accurately and choose a box that provides enough space for them, including any additional packaging materials such as padding or cushioning.

Additional Packaging Materials

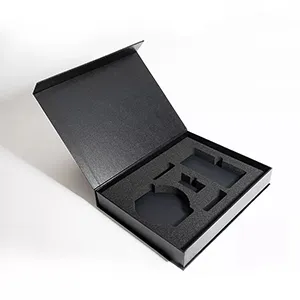

Additional packaging materials, such as bubble wrap, foam inserts, or packing peanuts, can affect the box size needed. These materials add extra volume and may require a larger box to ensure proper protection. It's essential to consider the type and amount of packaging material needed when determining the box size.

Shipping Method and Destination

The shipping method and destination should also be considered when selecting the appropriate box size. Different shipping carriers may have size restrictions or charge additional fees for oversized packages. It's crucial to research carrier requirements and restrictions to avoid any unexpected fees or delays in delivery.

The fragility of the Products

The fragility of the products being packaged is another important factor to consider. Fragile items require extra cushioning and support to prevent breakage during transportation. A larger box may be needed to accommodate the necessary padding and cushioning material.

Stacking Limitations

Stacking limitations may also impact the size of the box needed. For example, if you plan to stack boxes during transportation or storage, it's important to select a box size that will stack neatly and safely without risking damage to the products inside.

Order Volume

The volume of orders may also impact box size selection. If you are packaging and shipping large volumes of products, a smaller box may be more efficient, as it can be packed more tightly and will take up less space during transport. On the other hand, if you are shipping fewer products, a larger box may be more appropriate to ensure proper protection and support.

Choosing the Right Shipping Box Sizes

Measure Your Products

The first step is to accurately measure the dimensions of your products, including length, width, and height. Measure the largest dimensions to ensure that the box will accommodate the product. Use a tape measure or ruler to measure the product dimensions.

Calculate the Volume

Once you have measured your products' dimensions, calculate their volume by multiplying the length, width, and height. This will help you determine the minimum box size needed to accommodate your products. For example, if your product is 12 inches long, 6 inches wide, and 4 inches high, the volume calculation would be 12 x 6 x 4 = 288 cubic inches.

Add Padding and Cushioning

If you plan to use additional padding or cushioning material, add the volume of these materials to your product volume calculation. This will help you determine the appropriate box size for the product and the additional materials. For example, if you plan to use 2 inches of bubble wrap around your product, add 2 inches to the height, width, and length dimensions before calculating the product volume.

Consider Shipping Carrier Requirements

Research the requirements of the shipping carrier you plan to use to determine if there are any shipping box size restrictions or additional fees for oversized packages. This will help you select an appropriate box size that meets carrier requirements. For example, some carriers may have size restrictions for packages that exceed a certain length, width, or height.

Choose the Right Box Size

Once you have completed the above steps, you can choose the appropriate box size for your product. Select a box slightly larger than the calculated volume to ensure enough space for the product and any additional padding or cushioning material. Ensure the box is sturdy enough to support the product's weight and additional materials.

Here are some examples of different box sizes and the types of products they may be suitable for:

- Small Boxes: Small boxes are typically less than 16 inches long and suitable for small or lightweight products, such as jewelry, cosmetics, and small electronic devices.

- Medium Boxes: Medium boxes are typically between 16 and 24 inches long and can be suitable for various products, including books, clothing, shoes, and small appliances.

- Large Boxes: Large boxes are typically between 24 and 36 inches long and can be suitable for larger and heavier products, such as kitchen appliances, home decor, and sports equipment.

- Extra-Large Boxes: Extra-large boxes are typically over 36 inches long and suitable for very large or bulky products, such as furniture, televisions, and exercise equipment.

When selecting a box size, it's important to consider the dimensions and weight of the product being shipped. A box that is too small may need to provide more space for proper cushioning and protection. At the same time, a too-large box may be more expensive to ship and require additional cushioning materials to prevent the product from shifting during transport. It's also important to consider the shipping method and destination when selecting a box size. For example, if the product is shipped internationally, it may be subject to different size restrictions or fees. Additionally, if the product is being shipped via air, it may be subject to dimensional weight pricing, which can significantly increase shipping costs for larger boxes.

Box size can have a significant impact on packaging efficiency and cost. The appropriate box size can reduce material waste and lower shipping costs. When a box is too small for the product being shipped, it may require additional padding and cushioning materials to protect it during transit. This can result in excess material waste and increased packaging costs. Similarly, when a box is too large for the product being shipped, it may result in higher shipping costs due to dimensional weight pricing. Dimensional weight pricing is a shipping industry practice used by carriers to charge for the space a package takes up on a truck or plane. It is based on the package size rather than its actual weight. For example, a lightweight but large package may be charged based on size rather than weight. This can result in significantly higher custom size shipping box costs.

Custom Size Cardboard Box Packaging Efficiency and Cost

Custom sized cardboard boxes' efficiency and cost are closely related to the box size used for packaging. Using the right box size can ensure the product's safety during shipping, improve packaging efficiency, and reduce costs.

When a too-large box is used for packaging, it wastes space and increases shipping costs. This is because larger boxes require more cushioning materials to prevent the product from shifting during transport and may also be subject to dimensional weight pricing, which can significantly increase shipping costs. On the other hand, using cardboard boxes custom size and that are too small can damage the product during transport, as it may need to be adequately protected.

Tips to optimize box size and reduce shipping costs

Measure your product accurately

Take accurate product measurements, including length, width, and height, to determine the appropriate box size for optimal packaging.

Choose the right type of box.

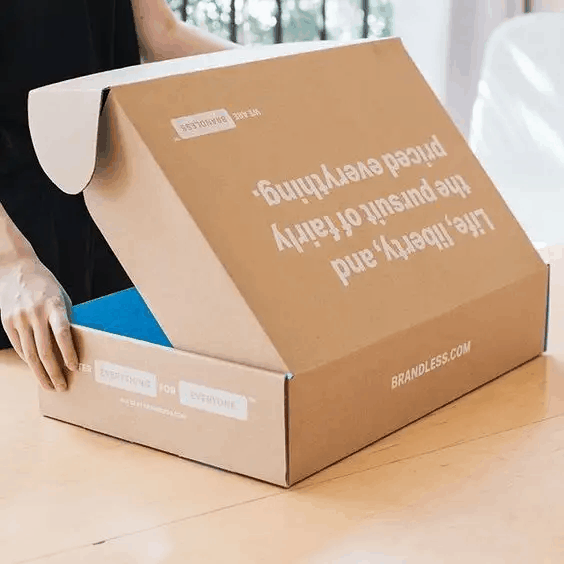

Consider the type of box needed for your product, such as corrugated boxes or mailer boxes, as each has its size limitations and may affect shipping costs.

Use filters and cushioning materials wisely.

Use filters and cushioning materials, such as bubble wrap or packing peanuts, to fill any space in the box and ensure the product is adequately protected during transport.

Consider the shipping method.

Different shipping methods have different size and weight limitations, so choose a box size that meets the shipping method's requirements.

Minimize packaging material

Use the minimum amount of packaging material required to protect the product and avoid using excessive materials that increase the size and weight of the package.

Custom Size Corrugated Boxes Regulations and Restrictions

Regarding custom size corrugated shipping boxes, different carriers have regulations and restrictions regarding box size. These regulations and restrictions are in place to ensure that packages can be safely transported and delivered without causing harm to the carrier's personnel, equipment, or other packages. Box size can also affect shipping rates and fees, as carriers may charge additional fees for packages that exceed certain size or weight limits.

Here are some examples of box size regulations and restrictions for popular shipping carriers:

United States Postal Service (USPS)

The USPS has size restrictions for both domestic and international shipping. For domestic shipping, packages cannot exceed 108 inches or a combined length and girth of 130 inches. For international shipping, packages cannot exceed 60 inches or a combined length and girth of 108 inches.

FedEx

FedEx has a maximum size limit of 108 inches in length and girth combined for most shipments. Additional restrictions may apply for international shipments.

UPS

UPS has a maximum size limit of 165 inches in length and girth for most shipments. Additional restrictions may apply for international shipments.

It's important to note that box size can also affect shipping rates and fees. Most carriers use a pricing structure based on both weight and dimensional weight, which is calculated by multiplying the package's length, width, and height. This means that even if a package is light, it may still be subject to higher shipping rates if larger. To ensure that packages meet carrier regulations and restrictions, it's important to accurately measure and weigh the package, choose the appropriate box size, and use the right packaging materials. This helps minimize shipping fees and ensures the package is delivered safely and efficiently.

Custom Corrugated Sized Boxes

Custom size corrugated boxes are manufactured according to specific size requirements that may not be available as standard sizes. These boxes are designed to fit a product's specific dimensions and weight while also providing the necessary protection during shipping and handling. Corrugated box sizes are ideal for businesses that ship products of varying sizes and quantities. They can be customized with a company's branding and logo for added marketing and recognition.

Steps to Follow for Measuring the Size of a Box

To take the size of a box, you will need to measure the length, width, and height. Here are the steps to take:

- Place the box on a flat surface, such as a table or the floor.

- Measure the length of the box from one end to the other using a measuring tape.

- Measure the box's width from one side to the other using a measuring tape.

- Measure the height of the box from the bottom to the top using a measuring tape.

- Record the measurements in inches or centimeters, depending on your preferred unit of measurement.

- If the box has an irregular shape, measure the longest length, the widest width, and the highest point to get the dimensions of the box.

- To calculate the total volume of the box, multiply the length, width, and height together. This will give you the box's total cubic inches or cubic centimeters.

By taking accurate measurements, you can select the appropriate box size for your packaging needs, which can help to protect your products during shipping and reduce shipping costs.

Your email address will not be published. Required fields are marked