Blog description in detail:

Benefits of custom printed boxes

Using custom printed boxes has several advantages for businesses. Here are some benefits of using custom printed boxes for your business:

Boost Your Branding with Custom Printed Boxes

Custom printed boxes provide an excellent opportunity for businesses to promote their brand and increase brand recognition. Adding your logo, brand colors, and other branding elements to your boxes allows you to create a unique identity for your business that customers will recognize and remember. Every time customers receive a product in your custom box, they will be reminded of your brand, which can help increase brand loyalty and awareness.

Protect your products with custom printed boxes

Our custom boxes are made with high-quality materials to protect your products during shipping and storage. We understand how important it is to ensure that your products arrive in perfect condition, so we use durable materials that can withstand the rigors of shipping and handling. Using our custom printed boxes reduces the risk of product damage, returns, and customer complaints, which can help improve your bottom line.

Professionalism

Custom box printing gives your products a professional and polished look that can help increase customer confidence in your brand. Adding branding elements to your boxes allows you to create a cohesive and professional image for your business that customers will appreciate. This can help build trust and credibility with your target audience, leading to increased sales and customer loyalty.

Eco-Friendly

At CustomBoxline, we are committed to promoting sustainability and reducing waste. That's why our boxes are made from recycled and environmentally friendly materials. Using our custom printed boxes, you can demonstrate your commitment to sustainability and appeal to customers who value eco-friendly products. This can help improve your brand image and reputation and attract new customers looking for environmentally responsible businesses to support.

Using custom printed boxes can provide several benefits for businesses, including increased brand recognition, improved product protection, enhanced professionalism, and a commitment to sustainability. Contact us today to learn how we can help you create custom printed boxes that meet your unique needs and requirements.

Ordering custom printed shipping boxes from CustomBoxline

Ordering custom printed shipping boxes wholesale from CustomBoxline is straightforward. Here is our process:

Contact us: You can contact us via our website, email, or phone to discuss your customization needs.

Provide specifications: Let us know your box size, shape, and other requirements. We will provide you with a quote and design mockup.

Approve design: We will start creating custom printed boxes once you approve.

Delivery: We will deliver your custom boxes to your doorstep.

Unveiling the printing process for custom printed cardboard boxes

Design Creation: The first step in printing printed cardboard boxes is creating the design. This involves creating a digital file with all design elements, such as logos, text, images, and colors. The design is created using specialized design software and must be formatted to the exact size and specifications of the cardboard box.

The Pre-Press Process

Pre-press is the preparatory stage of the printing process before the printing press produces the final printed product. The pre-press stage involves several steps, including:

1- Design File Preparation: The design file must be prepared for a custom printed cardboard box before printing begins. This may involve checking the design for errors, ensuring the correct colors, and converting the file to the correct format for the printing press.

2- Color Separation: Color separation involves dividing the design into different color layers to create individual printing plates. Each color in the design is separated onto a different plate, which is then used to apply ink to the paper or other substrate during printing.

3- Image Setting: Image setting involves preparing the images in the design file for printing. This may include ensuring the images are at the correct resolution, adjusting the color balance, and sharpening the image as necessary.

4- Proofing: Once the design file has been prepared, a proof is created to ensure the final printed product looks as expected. This may involve creating a digital or physical proof, which is then reviewed for accuracy by the designer or customer.

5- Plate Making: The printing plates are created once the proof has been approved. The plates are typically made from metal or plastic and contain the design elements that will be printed onto the substrate.

6- Press Setup: After creating the plates, they are mounted onto the printing press. The press is set up according to the job's specifications, including ink color, paper type, and print run length.

The pre-press stage is an integral part of the printing process, as it ensures that the final printed product is accurate, high-quality, and meets the customer's requirements. By adequately preparing the design file, separating the colors, and creating accurate proofs and printing plates, the pre-press stage can minimize errors and ensure that the final printed product is of the highest possible quality.

Bringing Your Boxes to Life: The Printing Process

The printing process for cardboard boxes typically uses a flexographic printing method. The plates are mounted onto a printing press, and the cardboard box is fed through the press. The ink is transferred from the printing plate onto the cardboard box using a series of rollers.

The importance of color matching in printing

Color matching in printing refers to ensuring that the colors in a printed piece accurately match the colors in the original design. This is important because colors vary depending on printing, ink, substrate, and other factors. Accurate color matching is essential to producing a high-quality printed piece that looks as intended.

There are several different methods used for color matching in printing:

1- Pantone Matching System (PMS): The Pantone Matching System is a standardized color-matching system that uses specific colors and formulas to ensure accurate color reproduction. PMS colors are often used for logos, branding, and other critical design elements.

2- Process Color: Process color, also known as CMYK (cyan, magenta, yellow, and black), is a four-color printing process used for full-color printing. The process works by combining the four colors in varying amounts to create a wide range of colors.

3- Spot Color: Spot color is a specific ink color used for a particular element in the design, such as a logo or text. Spot colors are often used in addition to process colors to ensure accurate color reproduction.

Color matching key factors to achieve accurate and consistent results

To achieve accurate color matching in printing, several factors must be taken into consideration:

1- Lighting: Lighting can affect how colors appear, so it is essential to evaluate printed samples in the same lighting conditions as the intended use.

2- Calibration: The printing equipment must be appropriately calibrated to print the colors accurately.

3- Color Profiles: Color profiles can be used to ensure that colors are being printed consistently across different devices and printing processes.

4- Proofs: Creating accurate proofs and reviewing them carefully can help to catch any color discrepancies before the final print run.

Color matching in printing ensures that the colors in a printed piece accurately match the colors in the original design. By using standardized color systems, properly calibrating printing equipment, and carefully reviewing proofs, accurate color matching can be achieved for high-quality printed pieces.

Elevate your custom printed boxes with professional finishing options

After the printing is complete, the cardboard box is sent to the finishing department. Here, additional finishing touches, such as varnish or a protective coating, are added to enhance the appearance and durability of the printed design.

Finishing in printing refers to the various processes after the printing to complete the final product. Finishing can include a range of tasks, such as cutting, folding, binding, coating, and more. Here are some of the most common finishing techniques in printing:

1- Cutting: Cutting involves using a guillotine or other cutting tool to trim the paper or substrate to the desired size and shape. This is typically one of the first finishing processes after the printing.

2- Folding: Folding involves creasing the paper or substrate along specific lines to create a desired layout or format. Common folding styles include half-fold, tri-fold, and gate-fold.

3- Binding: Binding involves attaching the pages of a book or other document. Standard binding methods include saddle stitching, perfect binding, and spiral binding.

4- Laminating: Laminating involves applying a thin layer of plastic film to the surface of the printed piece. This can help protect the piece from damage and add a glossy or matte finish.

5- Coating: Coating involves applying a liquid coating to the surface of the printed piece. This can be done to add protection, improve the appearance, or add special effects, such as a glitter finish.

6- Embossing/Debossing: Embossing and debossing are techniques used to create a raised or recessed design on the surface of the printed piece. This can add texture and dimension to the piece.

7- Foil Stamping: Foil stamping involves using a heated die to transfer a metallic foil onto the surface of the printed piece. This can add a shiny, metallic finish to the piece.

8- Die Cutting: Die cutting involves using a metal die to cut the paper or substrate into a specific shape or design. This can create custom shapes, such as product packaging or business cards.

Finishing is an essential part of the printing process that adds the final touches to the printed piece. Using various techniques, finishing can enhance the printed piece's appearance, functionality, and overall quality.

Stringent Quality Control Measures

Quality control is an essential aspect of the printing process for cardboard boxes. Each box is inspected to ensure the design is aligned correctly, the colors are accurate, and the finished product meets the required specifications.

Quality control in printing refers to ensuring that the printed materials meet the necessary standards of quality and accuracy. Quality control aims to catch any errors or inconsistencies in the printing process before the final product is delivered to the customer. Here are some of the steps involved in quality control in printing:

Pre-Press Check: Quality control starts with the pre-press check, done before the printing process begins. This involves reviewing the artwork, checking for errors, and ensuring the file is formatted correctly for printing.

Color Management: Ensuring accurate color reproduction is a critical aspect of quality control in printing. This involves using calibrated equipment, color profiling, and careful monitoring of the printing process to ensure that the colors in the final product match the intended design.

Press Check: During the printing process, a press check involves inspecting the printed materials as they come off the press to ensure that the colors, registration, and overall quality meet the necessary standards.

Finishing Check: The finished product goes through a finishing check once the printing is complete. This involves inspecting the materials for any errors or inconsistencies that may have occurred during the finishing process, such as cutting or binding.

Final Inspection: Before the printed materials are delivered to the customer, a final inspection is done to ensure the quality is up to standard. This may involve checking for defects or errors and ensuring that the materials meet the customer's specifications.

Quality control in printing is a crucial part of the printing process. By implementing a rigorous quality control process, printing companies can ensure that the final product meets the necessary standards of quality and accuracy, which can help to build trust and confidence with their customers.

The printing process for printed cardboard boxes involves designing the artwork, preparing the design for printing, printing the design using a flexographic method, color matching, finishing the product, and conducting quality control. CustomBoxline uses state-of-the-art printing technology and high-quality materials to create custom cardboard boxes that meet our customers' specific needs and requirements.

Make your gift stand out with our custom printed gift boxes

Custom printed gift boxes are packaging boxes that can be customized to fit specific needs, including branding, personalization, size, shape, material, and finishing options. These boxes can be designed to match a particular theme, occasion, or brand and customized with logos, images, and text. Printed gift boxes offer several benefits, including:

- Versatility: Custom printed gift boxes wholesale can be designed for a wide range of occasions, including weddings, corporate events, and holidays.

- Personalization: Custom printed gift boxes allow for a more personalized gift-giving experience, making them more memorable.

- Protection: Custom printed gift boxes are made from high-quality materials, which provide better protection for the contents during shipping and storage.

- Environmentally friendly: Many custom printed gift boxes are made from recycled or sustainable materials, which makes them an eco-friendlier option.

- Better branding: Custom printed gift boxes can be designed with your brand's logo and colors, which helps to increase brand recognition and awareness.

Custom printed gift boxes can be created using different materials such as cardboard, paperboard, and corrugated cardboard. Additionally, custom printed gift boxes can be produced using different printing techniques, including offset printing, digital printing, or screen printing. Finishing options can also be added to custom printed gift boxes to enhance their appearances, such as foil stamping or embossing.

Choosing the perfect material for custom printed packaging boxes

Luxury packaging typically involves using high-quality materials that convey a sense of elegance, sophistication, and exclusivity. The specific material or box chosen for luxury printed packaging boxes depends on the product being packaged and the brand image and target audience. Here are some materials and boxes commonly used for luxury packaging:

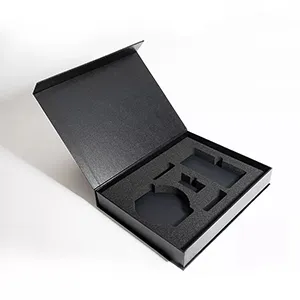

Rigid Boxes

Rigid boxes are made of thick cardboard or paperboard, which makes them very sturdy and durable. To create a luxurious and high-end look, they can be customized with various design elements, such as foil stamping, embossing, and specialty coatings. Rigid boxes are commonly used for high-end packaging products like jewelry, cosmetics, and perfume.

Folding Cartons

Folding cartons are made of paperboard and are commonly used for luxury packaging of small to medium-sized products like electronics, accessories, and confectionery. They can be customized with special finishes, such as foil stamping and embossing, to create a premium look and feel.

Metal Tins

Metal tins are famous for luxury packaging products like tea, candles, and gourmet foods. They offer a high-end look and feel and can be customized with embossing, debossing, and other decorative elements.

Glass Jars and Bottles

Glass jars and bottles are commonly used for the luxury packaging of high-end products like cosmetics, perfumes, and gourmet foods. They offer a high-end, premium look and feel and can be customized with various design elements like embossing and silk-screen printing.

Wood Boxes

Wooden boxes are a popular choice for the luxury packaging of products like wine, spirits, and gourmet foods. They offer a natural and sophisticated look and feel and can be customized with branding and other design elements.

Custom packaging boxes printed often involve the use of high-quality materials like rigid boxes, folding cartons, metal tins, glass jars and bottles, and wood boxes. These materials can be customized with various design elements to create a premium, high-end look and feel that conveys a sense of exclusivity and sophistication.

Luxury packaging: Are the custom printed corrugated boxes the preferred option?

While rigid boxes are a popular packaging option for luxury items, it is not necessarily the only favored packaging option. The specific packaging option chosen for luxury items depends on the type of product being packaged, the brand image, and the target audience. Other packaging options, such as metal tins, glass jars and bottles, folding cartons, and wooden boxes, are also commonly used for luxury packaging. The packaging option chosen for luxury items is meant to convey to the consumer a sense of exclusivity, sophistication, and quality. Selecting a custom corrugated box printing option that protects the product during shipping and storage, enhances the overall consumer experience, and reinforces the brand image is essential.

Rigid or setup boxes are high-quality packaging commonly used for luxury items. Rigid boxes are made of thick, sturdy cardboard or paperboard, which makes them durable and resistant to damage. The box consists of two main parts: the base and the lid. The base is usually made of thicker board, while the lid can be made of the thinner board to create a seamless and elegant appearance. Rigid boxes can be customized in various ways, including size, shape, and design. To create a premium look and feel, they can also be decorated with various finishes, such as foil stamping, embossing, debossing, and specialty coatings. These design elements reinforce brand identity and create a memorable unboxing experience for the consumer.

Rigid boxes are commonly used for high-end packaging products like jewelry, cosmetics, and electronics. Custom printed corrugated shipping boxes are also famous for gift packaging, providing a luxurious and elegant appearance. Additionally, rigid boxes can be reused and repurposed, increasing their value and appeal. Rigid boxes are a premium packaging option that conveys a sense of exclusivity and quality to the consumer. They offer a high-end look, feel, and protection for the product during shipping and storage.

CustomBoxline is a company that specializes in manufacturing custom boxes. They offer a range of options for businesses looking to package their products in a professional and eco-friendly way. Custom printed boxes with a company's branding offer several benefits, including increased brand recognition and product protection. Pre-press, color matching, finishing, and quality control are all critical aspects of the printing process that ensure the final product meets the company's standards. Corrugated boxes are a popular choice for packaging luxury and gift items, while rigid boxes are a premium option that conveys a sense of exclusivity and quality. Ultimately, the packaging option chosen should be based on the business's specific needs and target audience.

Your email address will not be published. Required fields are marked