Blog description in detail:

What are printed cardboard boxes?

Printed cardboard boxes are corrugated, fluted sheets sandwiched between two flat sheets. The fluted sheet provides strength and cushioning, while the flat sheets provide a smooth surface for printing. Printed cardboard boxes can be customized with graphics, logos, text, and other design elements to make them more attractive and eye-catching.

Purpose of custom printed cardboard boxes

Printed cardboard boxes serve various purposes, keeping users and retailers in consideration. Following are some of the most common purposes of custom cardboard boxes printing.

- custom printed cardboard box is commonly used for packaging various products. They protect the product from damage during transportation and provide a platform for branding and advertising.

- Printed cardboard boxes can be used for the storage of goods, both at home and in businesses.

- Printed cardboard boxes are widely used for shipping goods domestically and internationally.

- Printed cardboard boxes can reinforce a company's branding efforts by including the company's logo, colors, and other design elements.

- Printed cardboard boxes can serve as an advertising medium, promoting the product or company.

Types of printed cardboard boxes wholesale

Printed cardboard boxes come in different types, each with unique characteristics and use. Here are the most common types of printed cardboard boxes:

Corrugated Printed Cardboard Boxes

Corrugated cardboard boxes are the most common type of printed cardboard box. They are made of three layers of paper, with a fluted sheet sandwiched between two flat sheets. The fluted sheet provides cushioning and strength, making them ideal for shipping and storing products. Custom printed cardboard boxes wholesale is available in various sizes and can be customized with different printing techniques, including flexography, lithography, and digital printing.

Folding Printed Carton Boxes

Folding carton boxes are lightweight and often used for retail packaging. They are made of paperboard, thinner than the material used for corrugated cardboard boxes. Folding carton boxes are usually pre-glued and shipped flat, making them easy to store and transport. To create attractive designs and graphics, they can be customized with high-quality printing techniques, such as offset printing.

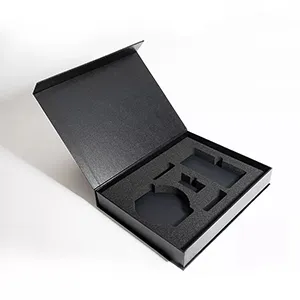

Rigid Printed Cardboard Boxes

Rigid boxes are the most premium type of printed cardboard boxes. They are made of sturdy cardboard and are often used for luxury products like cosmetics, electronics, and jewelry. Rigid boxes are highly customizable and can be printed with high-quality techniques, including hot stamping and embossing, to create a premium look and feel. They are typically more expensive than other printed cardboard boxes but offer superior durability and protection.

Advantages of printed cardboard packaging

Printed cardboard boxes offer several advantages over other packaging materials. Here are some main advantages of using printed cardboard boxes for your business.

Customization of Printed Cardboard

One of the main advantages of printed cardboard boxes is their ability to be customized. With advanced printing technologies, companies can create unique designs and graphics on their packaging, allowing them to stand out from competitors. Customized printing can reinforce a company's branding efforts and create a memorable customer experience.

Sturdy and Durability

Custom printed cardboard packaging is known for their durability. They are sturdy and can protect products from damage during transportation and storage. Corrugated cardboard boxes, in particular, offer excellent cushioning and can absorb shock and impact, making them ideal for shipping fragile or delicate items.

Cost-Effective and Budget Friendly

Printed cardboard boxes are a cost-effective option for packaging products. They are cheaper than many other packaging materials, such as plastic or metal, and can be manufactured in large quantities, further reducing costs. They are also lightweight, which can reduce shipping costs and make them more environmentally friendly.

Biodegradable and Environmentally Friendly

Printed cardboard boxes are an environmentally friendly option for packaging products. They are made of renewable materials, such as paper and cardboard, and can be easily recycled. Recycling printed cardboard boxes can reduce waste and conserve natural resources. Additionally, many companies are now using sustainable materials for their packaging, such as recycled paper and soy-based inks, further reducing their environmental impact.

Versatile Packaging Solution

Printed cardboard boxes are highly versatile and can be used for various products. They can be customized to fit any size or shape, making them suitable for products of varying dimensions. They can also be used for different industries, such as food and beverage, electronics, and cosmetics.

Ease of Handling

Printed cardboard boxes are easy to handle, both for manufacturers and consumers. They are lightweight and can be stacked, making them easy to store and transport. Printed cardboard boxes are easy for consumers to open and dispose of, compared to other packaging materials that may require tools or special instructions.

Advertising Opportunity

Printed cardboard boxes offer a unique opportunity for companies to advertise their products. With customized printing, companies can include product information, company logos, and marketing messages on their packaging. This can create brand recognition and increase the chances of repeat purchases.

Protection Against Tampering

Printed cardboard boxes can also offer protection against tampering. Companies can prevent unauthorized product access with security printing techniques like holograms and watermarks. This can help to ensure product safety and prevent fraudulent activities.

Printed cardboard boxes offer several advantages over other packaging materials. They can be customized, durable, cost-effective, and environmentally friendly. Companies that use printed cardboard boxes can create a positive brand image, protect their products during transportation and storage, and contribute to sustainable packaging practices.

Uses of logo printed cardboard boxes

Printed cardboard boxes have many applications, including pharmaceutical, electronics, promotional, and gift packaging. The versatility of printed cardboard boxes makes them a popular choice for many industries and purposes. Printed cardboard boxes have a wide range of applications across different industries. Here are some of the most common applications of printed cardboard boxes:

Retail Business Packaging

Printed cardboard boxes are commonly used for retail packaging. They can be customized to match a company's branding and include marketing messages and product information. Retail stores use printed cardboard boxes to display and protect their products, and they can be easily stacked on shelves to maximize space.

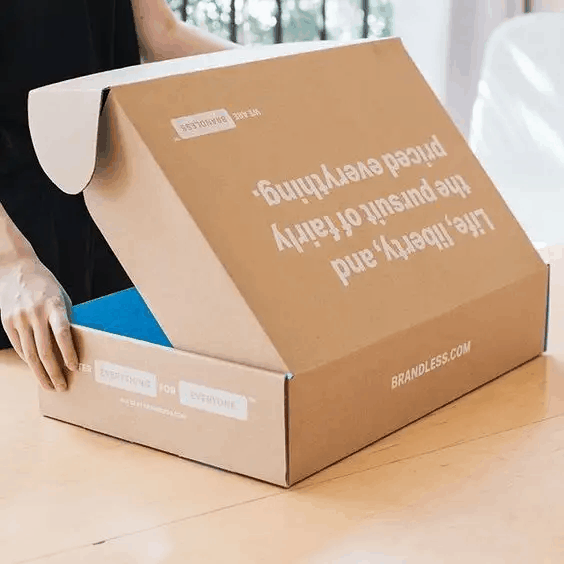

E-commerce Packaging Solution

With the rise of e-commerce, custom cardboard boxes printed are also being used for online retail packaging. E-commerce companies use printed cardboard boxes to ship products to customers, ensuring that they are protected during transportation. Printed cardboard boxes can also be customized with brand logos and marketing messages to create a memorable unboxing experience for customers.

Shipping and Logistics Needs

Printed cardboard boxes are ideal for shipping and logistics purposes. They are sturdy and can protect products from damage during transportation. Corrugated cardboard boxes, in particular, are commonly used for shipping as they offer excellent cushioning and can absorb shock and impact.

Food and Beverage Packaging Industry

Printed cardboard boxes are also used for food and beverage packaging. They are made from food-grade materials and can be printed with food-safe inks. Printed cardboard boxes are commonly used for pizza boxes, take-out containers, and beverage carriers.

Cosmetic Packaging Business

Printed cardboard boxes are also used for cosmetic packaging. They are ideal for packaging cosmetic products such as creams, lotions, and soaps. Printed cardboard boxes can be customized to match a company's branding and include marketing messages and product information.

Pharmaceutical Packaging

Printed cardboard boxes are commonly used for pharmaceutical packaging. They are ideal for packaging medications, vitamins, and supplements. Printed cardboard boxes can be customized to include dosage information, warnings, and other important product information.

Electronics Packaging

Printed cardboard boxes are also used for electronic packaging. They can be customized for electronic products like smartphones, laptops, and tablets. Printed cardboard boxes can protect electronic products during transportation and storage.

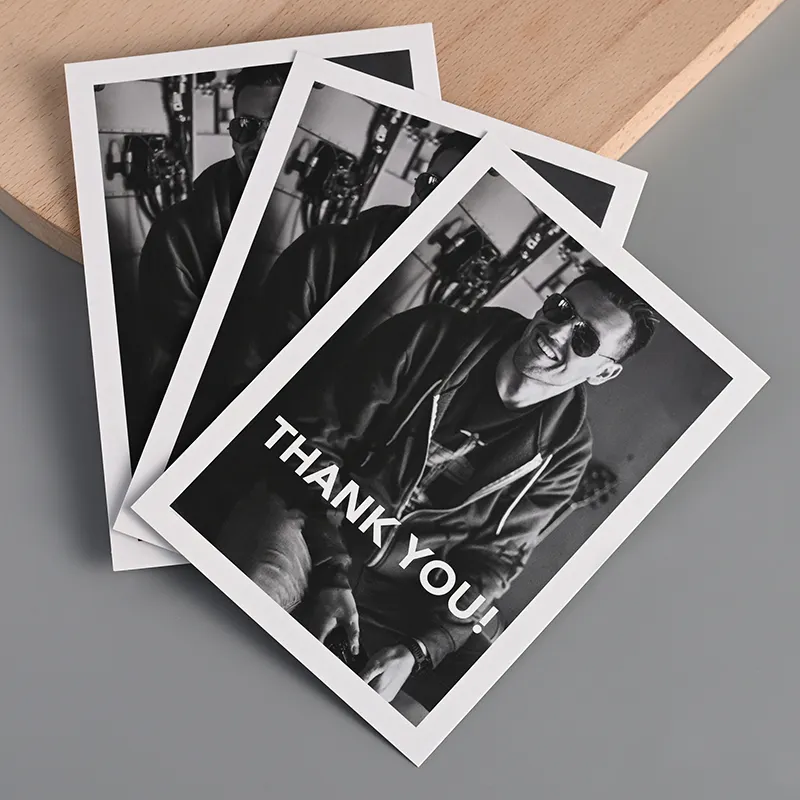

Custom Promotional Packaging

Printed cardboard boxes are often used for promotional purposes. Companies can use customized printed cardboard boxes as a giveaway or promotional item. Printed cardboard boxes can be designed with promotional messages, company logos, and other branding elements to create a lasting impression on customers.

Gift Packaging

Printed cardboard boxes are also used for gift packaging. They can be customized to match a specific occasion, such as birthdays, weddings, and holidays. Printed cardboard boxes can include gift messages, graphics, and other design elements to make the gift-giving experience special.

Trends in Printed Cardboard Boxes

The world of printed cardboard boxes is constantly evolving, and new trends are emerging to meet the demands of consumers and businesses. Here are some of the current trends in printed cardboard boxes:

Sustainable Packaging

As consumers become increasingly aware of environmental issues, there is a growing demand for sustainable packaging solutions. Printed cardboard boxes are eco-friendly, as they are made from renewable resources and can be easily recycled. Companies use recycled cardboard and vegetable-based inks to create sustainably printed cardboard boxes.

Digital Printing

Digital printing is a printing method that uses digital technology to print images directly onto cardboard boxes. This allows for faster production times and more precise color matching. Digital printing also allows for the customization of individual boxes, making it easier for businesses to create personalized packaging for their products.

Personalization

Consumers seek personalized experiences in all aspects of their lives, including packaging. Printed cardboard boxes are an excellent way to provide personalized packaging for products. Companies can use customized designs, graphics, and messages to create a unique packaging experience for their customers.

Interactive Packaging

Interactive packaging is a trend that involves creating packaging that engages the consumer. Printed cardboard boxes can be designed with interactive elements like QR codes, augmented reality, or gamification. This creates a memorable and engaging consumer experience and can help increase brand loyalty.

Minimalist Design

Minimalist design is a trend that has been gaining popularity in recent years. This design approach emphasizes simplicity and uses minimal graphics and text to create a clean and modern look. Printed cardboard boxes can be designed with a minimalist aesthetic, which can help to make the product stand out on store shelves.

Innovative Materials

In addition to sustainable cardboard materials, other innovative materials are used in printed cardboard box designs. For example, some companies use biodegradable materials, such as mushroom-based packaging, to create eco-friendly solutions. Other companies use materials like bamboo, hemp, or seaweed to create unique and sustainable packaging.

Smart Packaging

Innovative packaging is a trend that involves adding technology to packaging to provide additional functionality or information to the consumer. Printed cardboard boxes can be designed with intelligent packaging elements, such as RFID tags, QR codes, or NFC chips, that allow consumers to access additional information about the product or even reorder it with a simple scan.

Creative Shapes

While traditional rectangular or square shapes are still popular, creative and unique shapes are also gaining popularity in printed cardboard box designs. Companies use die-cutting and other techniques to create boxes with exciting shapes, such as hexagons, triangles, or custom shapes that fit the product.

How to choose the right cardboard box printing?

Choosing the correct printing cardboard boxes is an important decision that can impact your product's success. Here are some factors to consider when selecting the correct printed cardboard box:

Size and shape of your box

The size and shape of the box should be appropriate for the product you are packaging. It is essential to measure the dimensions of your product and select a box that fits it snugly to avoid damage during transportation.

Different materials for different box

Printed cardboard boxes are made from different materials, such as corrugated cardboard, folding cartons, and rigid boxes. Consider the material's durability, strength, and weight to ensure adequate protection for your product.

Printing Quality

The printing quality of the box is an essential factor to consider. The design and branding elements should be printed and visually appealing. Consider the printing method used, the quality of the inks, and the color accuracy.

Environmental Impact

As consumers become more environmentally conscious, choosing eco-friendly packaging options is becoming increasingly important. Look for printed cardboard boxes from recycled or sustainable materials like vegetable-based inks.

Quantity and Cost

Consider the boxes you need and your budget when selecting the correct custom cardboard printing. Some printing methods may be more cost effective for larger quantities, while others may be better suited for smaller runs.

Delivery and Storage

Consider the delivery and storage requirements for your product. Some printed cardboard boxes may be more suitable for stacking and storing, while others may be easier to transport and handle.

Strength and Durability

Consider the weight and fragility of your product and choose a box that provides adequate protection during shipping and handling. A strong and durable box will help to prevent damage or breakage during transit.

Branding and Design

Your printed cardboard box is an opportunity to showcase your brand and make a strong impression on consumers. Consider the design and branding elements, such as color scheme, logo, and messaging, to ensure they align with your brand identity.

Functionality

Consider the intended use of the box and any additional functionality it may require, such as easy opening, resealable flaps, or tear-off sections. These features can enhance the user experience and make your product more convenient.

Regulations and Compliance

Depending on the industry and product you are packaging, specific regulations or compliance requirements may need to be met. Ensure your printed cardboard box meets any necessary regulations or certifications, such as FDA food safety requirements or child safety regulations.

Customer Feedback

Finally, consider customer feedback and preferences when choosing the correct printed cardboard box. Ask for feedback from customers on previous packaging designs and incorporate their suggestions to improve the user experience and enhance customer satisfaction.

Quantity and Lead Time

Depending on the number of boxes you need, consider the lead time for production and delivery. Some printing methods may require longer lead times or have minimum order quantities, so it is essential to factor in production and delivery timelines.

Transportation and Handling

Consider your product's transportation and handling requirements and select a box that can withstand the rigors of transportation. For added strength, consider using double-walled or triple-walled corrugated cardboard if your product is shipped over long distances or through multiple handling stages.

Brand Experience

Your printed cardboard box can create a memorable brand experience for customers. Consider incorporating creative design elements or branding messages that enhance the customer experience and encourage repeat business.

Testing and Prototyping

Before ordering sizeable printed cardboard boxes, consider testing and prototyping to ensure the box fits your product. You can order small sample boxes to test and make necessary adjustments before placing a larger order. By considering these factors when choosing the correct printed cardboard box, you can ensure that your product is well-protected, visually appealing, functional, and aligned with your brand identity and customer preferences.

Your email address will not be published. Required fields are marked