-

Markets

Our extensive design library will unlock limitless possibilities for your brand packaging with its incredible range of innovative ideas! Step inside an oasis of creativity and innovation where inspiration abounds at every corner. Explore numerous captivating designs ranging from minimalist to bold, traditional to modern, and everything in between. Browse Library

Get creative and transform the packaging into art that represents both your brand and customers! Explore our gallary to get inspiration.

Start a Project -

Card

Stock

Partner with us for all your retail packaging needs and let us take your packaging to the next level! Contact us today to discuss your requirements.

Inquire More -

Design Templates

-

Popular

Items

Leading Items

Choose for our most ordered and trending box styles that are gaining popularity among brands and business owners to find their niche in retail competition.

-

Services

CAD Structures

Our innovative box structures for brand packaging feature unique designs that align with brand identity and product positioning.

3D Visuals

3D mock-up enables evaluation of box design, structure, dimensions, graphics, and appearance for feasibility and functionality.

Prototypes, Samples

CAD prototypes can help assessing packaging feasibility, functionality, and aesthetics by designers, manufacturers, and clients.

CustomBoxline offers a comprehensive range of products and services to assist brands in validating and testing their product packaging, ensuring that the final product aligns with their specifications.

Templates & Dielines

Access downloadable design templates and effortlessly generate realistic 3D Mock-ups for your product using online powerful design tool.

Start Designing -

Accessories

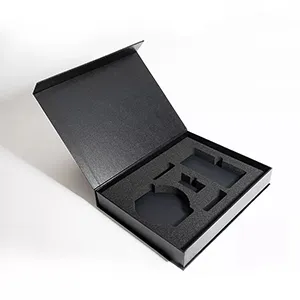

Die Cut Inserts

Durable Material for product protection and impactful unboxing experience.

Flexible Foam

Soft and flexible with excellent protection capabilities for fragile items.

Packing Dividers

Create pockets/ compartments to organize and seperate products inside the box.

Flocked Foam

Upscale presentation, optimal support and high impact protection during transit.

- Trendings

-

Promotional

Promotional Products

Choose for our most ordered and trending box styles that are gaining popularity among brands and business owners to find their niche in retail competition.

- Products List

- Blog

Free Worldwide Delivery on All Orders

Welcome to CustomBoxline! Explore the full spectrum of our customized products and services!

-

-

Mon-Fri (9am to 6pm)

1-800-205-9972

-

Hello,

My Account

Your email address will not be published. Required fields are marked